Get in touch

We have been focused on two-wheel vehicle welding for over 20 years

01. QUALITY

02. EXPERIENCE

03. INNOVATION

04. SERVICE

05. SUPPLY

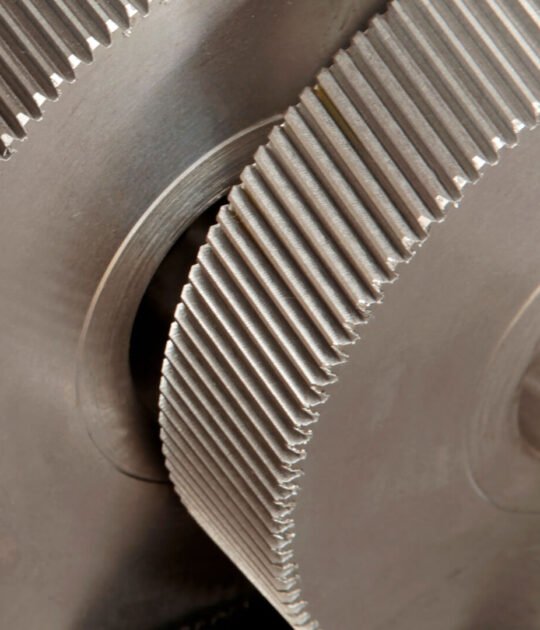

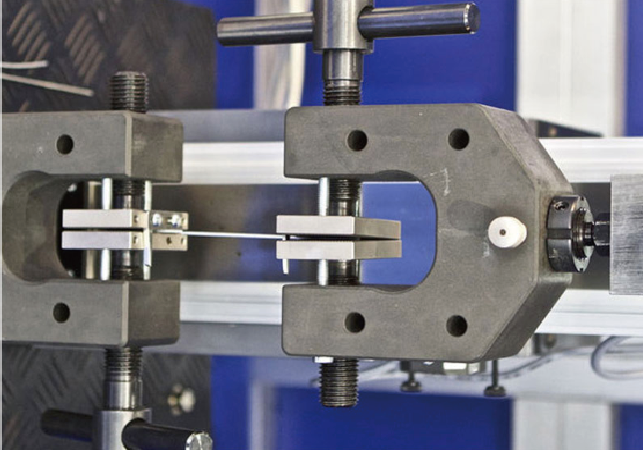

We maintain strict quality control throughout our manufacturing process, ensuring every welding wire meets international standards including AWS, JIS, and GB specifications. Our advanced testing facilities guarantee consistent performance and reliability.

With over 20 years of specialization in welding wire manufacturing, we have developed deep expertise in metallurgy and welding technology. Our experienced team understands the precise requirements of two-wheel vehicle applications.

We continuously invest in research and development to improve our welding wire formulations and manufacturing processes. Our innovation ensures superior arc stability, minimal spatter, and excellent mechanical properties.

We provide comprehensive technical support and customized solutions to meet specific customer requirements. Our responsive service team offers expert consultation and rapid quotation response within 24 hours.

Our robust production capacity and efficient logistics network ensure reliable delivery worldwide. We maintain adequate inventory levels and flexible production scheduling to meet urgent customer demands and long-term partnerships.

SFY INDUSTRY&TRADE

Tianjin SFY Co., Ltd. was established in 1999. It is a high-tech enterprise specializing in the field of aluminum alloy welding for two-wheeled vehicles. The company integrates R&D, production and service, and is committed to providing full-process service support for aluminum alloy welding wire and automated welding technology solutions to domestic and foreign customers. It has become an industry-leading comprehensive service provider of aluminum alloy welding materials and intelligent technology.

Stay informed on our latest news

our components are used in worldwide industrials

Years of Experience

Skilled Professionals

Partner Companies

Countries Worldwide

what our customers says

“SFY's LUNYAN™ ER4043 aluminum welding wire performs exceptionally well in our bicycle frame production. The wire provides excellent fluidity and minimal porosity, which is perfect for our aluminum alloy frame welding requirements. Since partnering with SFY, we've achieved 30% faster welding speeds while maintaining superior joint integrity. Their technical team's guidance on welding parameters has been invaluable in helping us optimize our entire production process.”

Nguyen Van Cuong

Technical Director“We produce over 8,000 aluminum bicycle frames monthly, and SFY's ER5356 aluminum welding wire consistently meets our strict requirements for stability and quality. The wire's excellent corrosion resistance and superior surface finish significantly reduce our post-processing workload. Most importantly, SFY's delivery is always on time and has never affected our production schedule.”